Masonry r2p Partnership Contractor Surveys Highlight Safety and Health Progress

The COVID-19 pandemic continues to be the number one safety and health concern across the country and a top priority for the masonry industry – especially as work moves inside during these colder months. But in addition to keeping ourselves and one another safe by limiting exposure to COVID-19, we cannot forget about the regular jobsite hazards faced by our members every day. Through an ongoing effort to survey both BAC members and contractors, the Masonry r2p Partnership (a collaborative effort between BAC, ICE, and IMI) has identified the safety and health hazards of highest concern and consistently demonstrated that we are making progress in addressing them (see 2017 Issue 2, p.18 for background).

In our final issue of 2019, we reported on the results of the 2019 BAC member survey (2019 Issue 4, pp. 26-27), which showed, for example, increases in the availability of engineering controls for silica dust and use of PPE for hearing protection, indicating the positive impact the Partnership has had on members’ safety and health.

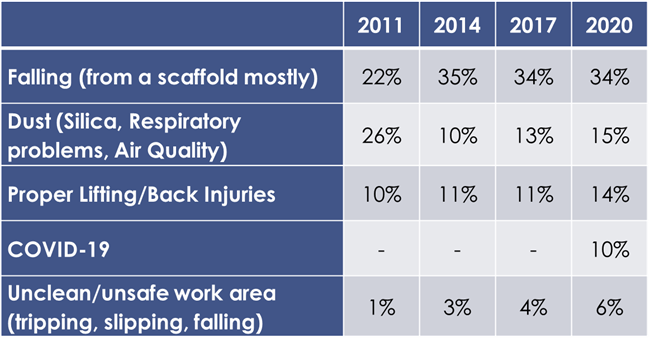

Since that issue was published, a 2020 contractor safety and health survey has also been completed. Due to the timing of the survey, which began in February 2020, many of the responses were collected after the pandemic began. Consequently, COVID-19 topped the list of concerns for 10% of contractors surveyed, but still fell behind the high-priority hazards of falling, dust and silica, and back injuries.

Since that issue was published, a 2020 contractor safety and health survey has also been completed. Due to the timing of the survey, which began in February 2020, many of the responses were collected after the pandemic began. Consequently, COVID-19 topped the list of concerns for 10% of contractors surveyed, but still fell behind the high-priority hazards of falling, dust and silica, and back injuries.

Top Concerns

Responses to questions about the implementation of controls reflected a similar picture to the one portrayed in the 2019 membership survey. Contractors report doing a better job overall of protecting members than in past years, and resources promoted by the Masonry r2p Partnership seem to be having an impact.

Dust & Silica

Dust & Silica

When it comes to controlling exposure to dust and silica, 99% of contractors indicated that they were somewhat or very familiar with OSHA’s silica standard – up from only 82% in 2017. Within that, three-quarters of those surveyed this year (77%) reported being very familiar - up from 39% in 2017. The percentage of contractors that had used the Silica-Safe.org website and exposure control planning tool grew significantly, from 5% in 2017 to 41% in 2020.

Strain & Sprain Injuries

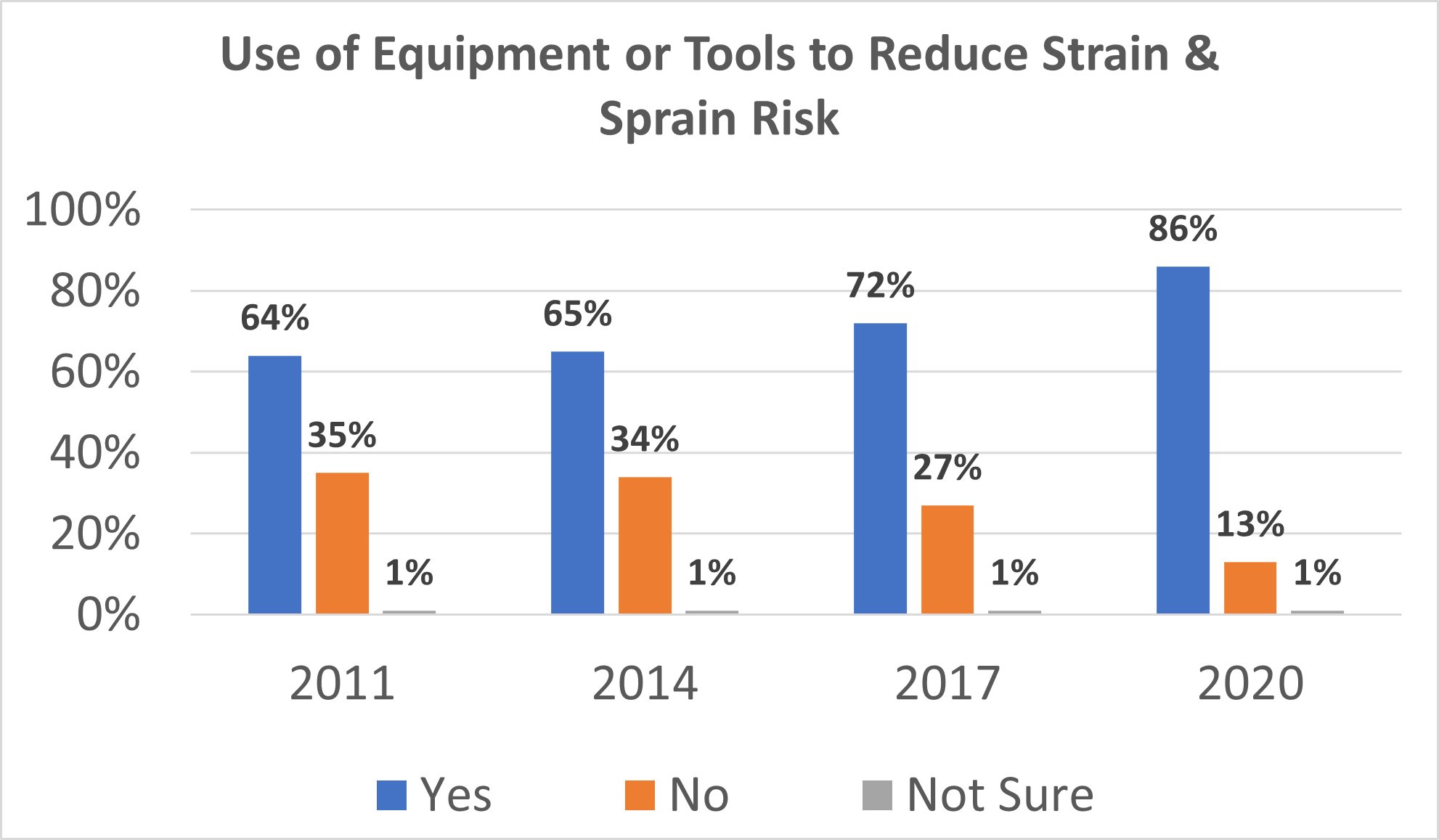

The Partnership also saw an increase in contractors’ efforts to prevent injuries from manual materials handling. When asked if they have used any equipment or tools designed to reduce a worker’s risk for injuries due to sprains and strains, 86% of contractors said “Yes”. A majority – 91% -- indicated that strategies to minimize manual materials handling are incorporated into site planning before the project even begins.

When exploring new ways such as robotics to address strains and sprains, only 14% of contractors surveyed had used bricklaying or demolition robots on a jobsite, but an additional 13% had seen them in use by others. Similarly, less than 3% of respondents had either used or seen an exoskeleton on the job, but only 8% were completely unfamiliar with this type of equipment.