Laser Cleaning Technology Expands BAC Work Opportunities

JOURNAL: ISSUE 1 - 2017

The growing use of lasers in masonry restoration as well as advancements in laser technology offer unique opportunities for BAC members and signatory contractors. The first large-scale masonry laser cleaning project was implemented in 2004 and since then laser has begun to play an increasing role in high-profile restoration projects.

Laser was selected as the preferred method of cleaning for the West Block of the Canadian Parliament Building in Ottawa, Canada, a 5-year project recently executed by BAC Local 7 Canada members employed by signatory contractors RJW-Gem Campbell Stonemasons Inc. (Ottawa, ON) and the Limen Group (Toronto and Ottawa/Kingston, ON and Maple Ridge, BC).

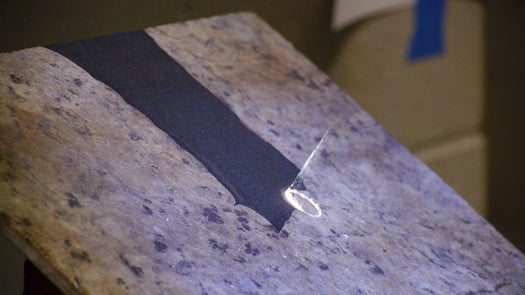

Laser is an effective way of cleaning certain types of accumulated surface dirt on various types of masonry, as well as on other materials including metals and wood. Laser is also an environmentally-friendly cleaning system and is essentially a “dry” means of cleaning, meaning that no water, chemical, or abrasive is required for containment or disposal. The laser ablates, or vaporizes, the surface dirt exposing the cleaned surface beneath.

Laser equipment currently being manufactured is highly sophisticated, portable, and can be calibrated to various levels of cleanliness. This means that the laser operator has more control over the end product of the cleaning process. It also makes it possible for multiple operators on the project to achieve the same level of cleanliness so that there is no change from operator to operator. While laser is effective for certain types of surface dirt, it is not a “magic wand” for all types of masonry cleaning projects. In most instances, it is used together with other more common cleaning techniques to address stubborn soiling or areas of masonry that are heavily deteriorated and need a gentle approach. Laser still faces the challenge of being very expensive. However, manufacturers are making more of this equipment available for rental which makes it more cost effective.

In order to address the needs of the industry, BAC, IMI, and IMTEF have been working closely with the major laser manufacturers to develop training on laser use for masonry craftworkers. The first of these pilot laser training programs was implemented in November 2016 at the National Training Center with BAC Local 1 Maryland/Virginia/District of Columbia members employed by signatory contractor Lorton Stone of Springfield, VA. This three-day training program involved classroom instructions and hands-on exercises which enabled the participants to become certified to operate the GC Laser Systems. Programs like this keep BAC craftworkers on the cutting edge of technological advancements and offer signatory contractors with an opportunity to bid and secure projects that include a laser cleaning scope.