An Update from the Masonry r2p Partnership

When BAC, ICE and IMI joined forces with CPWR to make masonry jobs safer, priorities were set. As reported in past BAC Journals, awareness of noise hazards, silica, and risks to skin and hands, as well as use of safe practices – hearing protection, gloves, and water or vacuums to prevent silica exposure – have increased.

Our Masonry Research to Practice (r2p) Partnership has also taken the lead on supporting and influencing new research on priority areas that affect the safety and health of members. Many of BAC Local union officers, trainers, members and contractors have been and continue to be active participants in these research initiatives. With their help, we have been able to provide CPWR and NIOSH researchers with guidance on the types of research that should be conducted, expertise and input on the research once it is underway, and assistance with the recruitment of workers and access to training centers and jobsites– all critical to finding solutions to the hazards our members face. By working in partnership, headway has been made on the following research projects:

A NOISH team focused on identifying ways to lower silica dust exposures during tuckpointing recently completed testing of the Bosch mortar knife, Arbortech saw, an Armeg raking chisel, and a die grinder with diamond bits as possible safer alternatives to grinders. They found that all of those tools reduced silica exposures, with the mortar knife and the saw offering the most promising alternatives when it comes to reducing exposure. Based on those results and input from the Partnership and the trainers and members who helped with the study, the research team is developing PCC training resources on use of these alternatives.

The SAVE Ergonomics Training for Masonry Apprentices – previously written about at http://www.bacweb.org/journal/2017_03/safety2.php - is focused on increasing apprentices knowledge about strain and sprain (ergonomics) risks and ways to prevent injuries, along with teaching them how to speak up and prevent safety hazards. With the help of trainers and apprentices from across the country, the training program has been tested and revised over the last two years to ensure it meets members’ needs and trainer requirements. Based on their input, the research team updated the delivery platform of the training, reduced the number of required classes, added other training options such as the CPWR Foundations for Safety Leadership Training, and expanded the instructor guide. The final SAVE program has already been delivered to over 100 BAC-IMI trainers, and is currently being shared and integrated into our apprenticeship training nationwide.

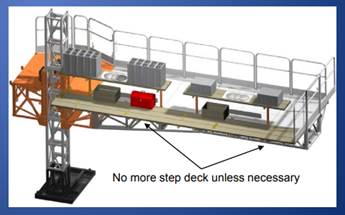

A NIOSH team studying mast climber use has focused on whether various production table designs intended to eliminate the need for a step deck may reduce falls and back injuries. Thanks to the members who responded to the Partnerships request for help, the researchers were able to test bricklaying risks when performed with (1) no production table, (2) a standard table design located parallel to the wall/work area on the opposite side of the worker, and (3) a new NIOSH designed L-shaped table that enables a worker to stack materials in front of their body and perpendicular to the wall/work area – eliminating the need to reach back for materials. The study found that while both the use of the existing industrial production table and the L-shaped table would reduce back-injury and postural-sway hazards while working on a mast climbing work platform, workers using the L-shaped table had a lower risk for a back injury. Now that the lab work is done, the researchers are going to job sites to test the stability of anchored mast climbing work platform in real-world conditions.

The good news is that we are making progress in addressing hazards and improving safety on masonry jobs, but safety is something we all need to focus on every day. What can you do:

- Protect your hands – keep them the “best hands in the business” by using tools that fit to prevent injuries and gloves to prevent – potentially career ending – dermatitis. Check out ChooseHandSafety.org to learn more.

- Protect your hearing. Hearing loss happens gradually and can be prevented. Use hearing protection. To learn more about hearing loss, noise hazards, and how to protect your hearing check out this Hazard Alert from CPWR (Noise and Hearing Loss - https://www.cpwr.com/sites/default/files/publications/Noise-Hazard-Alert.pdf).

- Do not let silica take your breath away – use water or a vacuum and know who your employer has assigned to make sure controls are being used and working properly (the competent person). Remember, protecting you from exposure to dangerous levels of silica dust is the law. Visit the website Work Safely with Silica (www.silica-safe .org) to learn more.